» Structure for Self Supporting Shelves

» Plate-web Girder Structure

» Trusses with Bolted Angles

» Trusses with Cold Rolled Sections

» Welded Trusses

» Mixed Structure

» Plate-web Girder Mezzanine with Steel Deck

» Special Tubular Structures

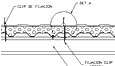

One of the systems used by CINTER for the covering of roofings is the Cinter 610 standing seam sheet system.

This type of roofing guarantees watertightness due to the absence of punctures and sheet overlaps as in the case of sinusoidal or trapezoidal sheets.

Sheets are cold rolled on-site with a special machine and are assembled all at once. Their length runs from the ridge to the gutter in a single piece, with no middle junctions, up to 65 m of maximum length and 2% of minimum slope. In the case of greater length skirts, in order to overlap one skirt with the other, it's necessary a leap of approximately 100 mm high. This guarantees that there are no sheet overlaps that may allow the access of water.

Once the sheet is assembled, and by means of a machine designed for that specific purpose, the sheet is seamed at 180º C in such a way that the roof remains watertight.

The encased clip fastening system is designed in order to allow the free expansion of the sheet whatever the length of the skirt may be.

This is the kind of roofing most used in the United States to cover large surfaces. CINTER has been using this technology for more than 10 years and have the machines for its implementation.

CINTER is also leader in the production of injected polyurethane panels, designed for cold storage works and construction in general.

INSULATING CORE: Made of rigid polyurethane foam, which results from the polymerization of isocyanate and polyol, in the presence of a foaming agent, in thermostatically-controlled hydraulic molds.

Average density: 40 Kg /m3

Thermal conductivity coefficient =0.019 kal/hm ºC (0.022 WmºK)

Anhygroscopicity: as it is an alveolar material of closed cells, it is highly water-resistant.

Other isolating components may also be used under special requirements.

CINTER TL ceiling and roof panels are construction elements that allow the installation of a wall, a roof or a ceiling completely finished in just one step by means of a dry assembly.

They are built in hydraulic molds for injection, under a strict quality control which guarantees the following characteristics:

- High thermal isolation.

- Optimal mechanical resistance.

- Easiness of assembly.

They are made up of a T-101 / T-98 -type cold rolled metal sheet (or steel deck-type sheet) side and another with no covering; a rigid polyurethane foam core is injected between them which performs mechanical and thermoacoustic functions.

INNER SIDE OF THE PANEL:

- Cold rolled galvanized steel sheet or Cincalum

- Cold rolled galvanized pre-painted steel sheet

TOP COVERING:

After the placement of the CINTER TL panel, we install the final watertight roof, which can be a CINTER 610 standing seam sheet, on the top exposed surface, allowing the free thermal expansion of the metal surface or watertight (asphalt, EPDM, etc) membrane. Thus, we can obtain an isolated watertight roof of a very good aesthetic resolution. The skirts can reach 70 meters, allowing minimum slopes (2-3%).

CHARACTERISTICS:

1- Length: according to the project (up to 12,000 mm)

2- Useful width: 980 mm

ACCESORIES:

This kind of roof allows the addition of polycarbonate barrel vaults and skylight flashings. For these cases, CINTER has standard solutions which guarantee the watertight security of the roof.

PANEL CHARACTERISTICS:

THICKNESS: 30 mm. (average thickness: 50 mm.),35 mm and 50 mm. (average thickness: 63 mm.)

LENGTH: According to the project (up to 12,000 mm.)

USEFUL WIDTH: 980 mm

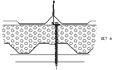

Section

Panel B Detail

CINTER TL panel with con CINTER 610 sheet

CINTER TL panel with asphalt membrane/coating

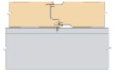

They are made up of 2 cold rolled metal sheet sides; a rigid polyurethane foam core is injected between them which performs mechanical and thermoacoustic functions.

PANEL SIDES:

- Cold rolled galvanized steel sheet

- Cold galvanized pre-painted steel sheet

- Cold rolled galvanized pre-painted steel sheet with PVC covering

- Stainless steel sheet

- Glass-reinforced plastic sheets

- Special coverings

JOINTS:

Completely watertight and airtight. The presence of the sealer guarantees the continuity of the vapor barrier offered by the steel sheet, in heating and cooling conditions. In cold storage buildings (of low temperature), the on-site joint injection guarantees the continuity of the isolating element. The fastening stays hidden in the panel joint, avoiding heat bridges

PANEL CHARACTERISTICS:

THICKNESS: 30 mm. (average thickness: 43 mm.),35 mm (average thickness: 48 mm.), and 50 mm. (average thickness: 63 mm.)

LENGTH: According to the project (up to 12.000 mm.)

USEFUL WIDTH: 980mm, 1.010 mm ó useful width of steel deck.